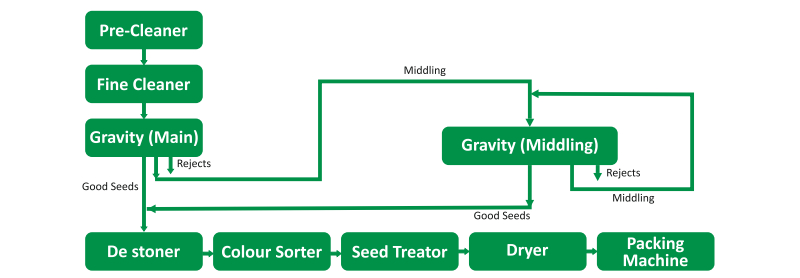

Life Cycle of Seed Processing:-

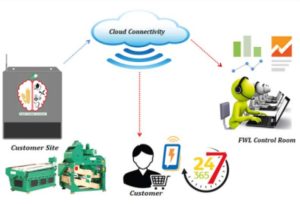

A Smart Device can monitor the Functioning of Agri machine and analyze the most critical value which leads to breakdown.

KS Equipment have been engaged in the design, installation and modernization of lots of Grain Processing Industries and color Sorter in India.

Copyright © 2024 KS Equipment | Designed By Orbit Infotech